Anchors Designed fit for purpose: All designs, materials, welds, qualification of welders, and tolerances have been driven by specific demands of marine anchoring where out on the water during installation, or in a storm event, quality counts beyond all else.

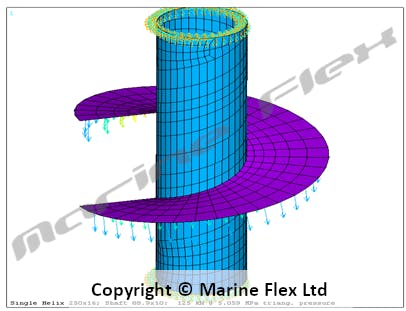

Empirically tested to destruction: all anchor components designed fit for purpose both structurally and geotechnically and have been empirically tested with destructive testing. Tube used is of specific grade to facilitate installation while mitigating the risk of over-torque or cold hardening failure during installation.

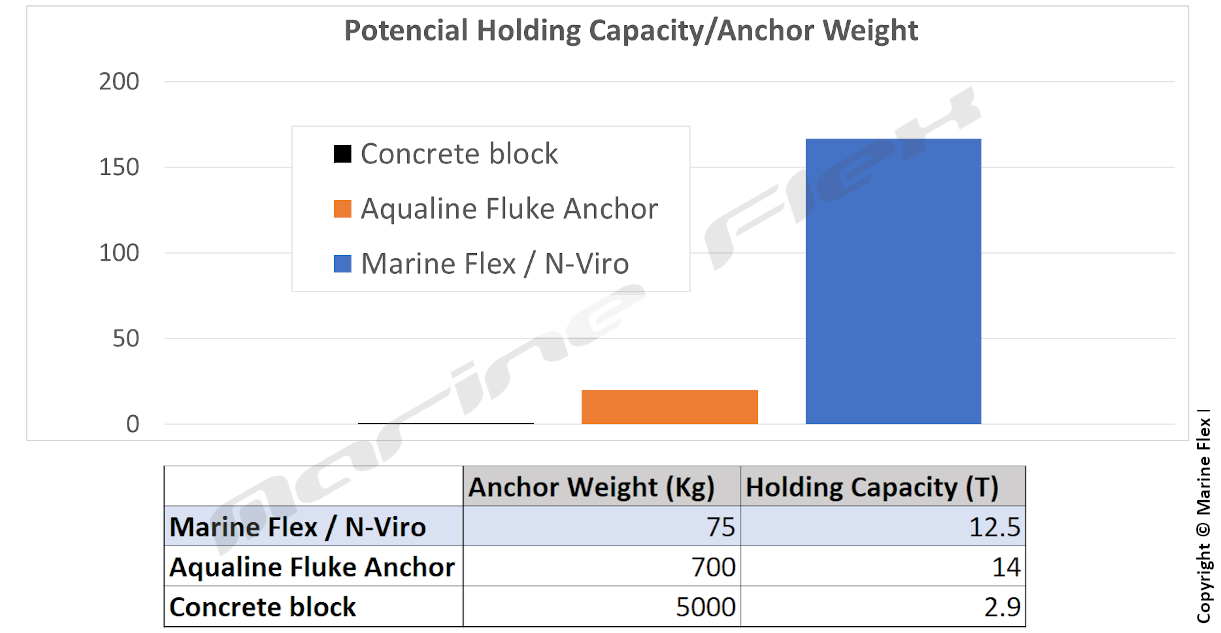

Shaft-less anchors: Our unique shaftless anchors lead effectiveness and efficiency in load with incomparable weight to load capacity ratios.

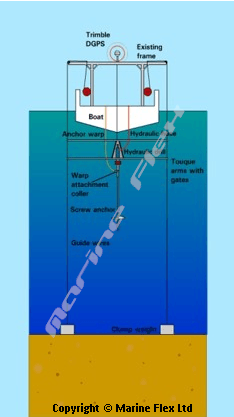

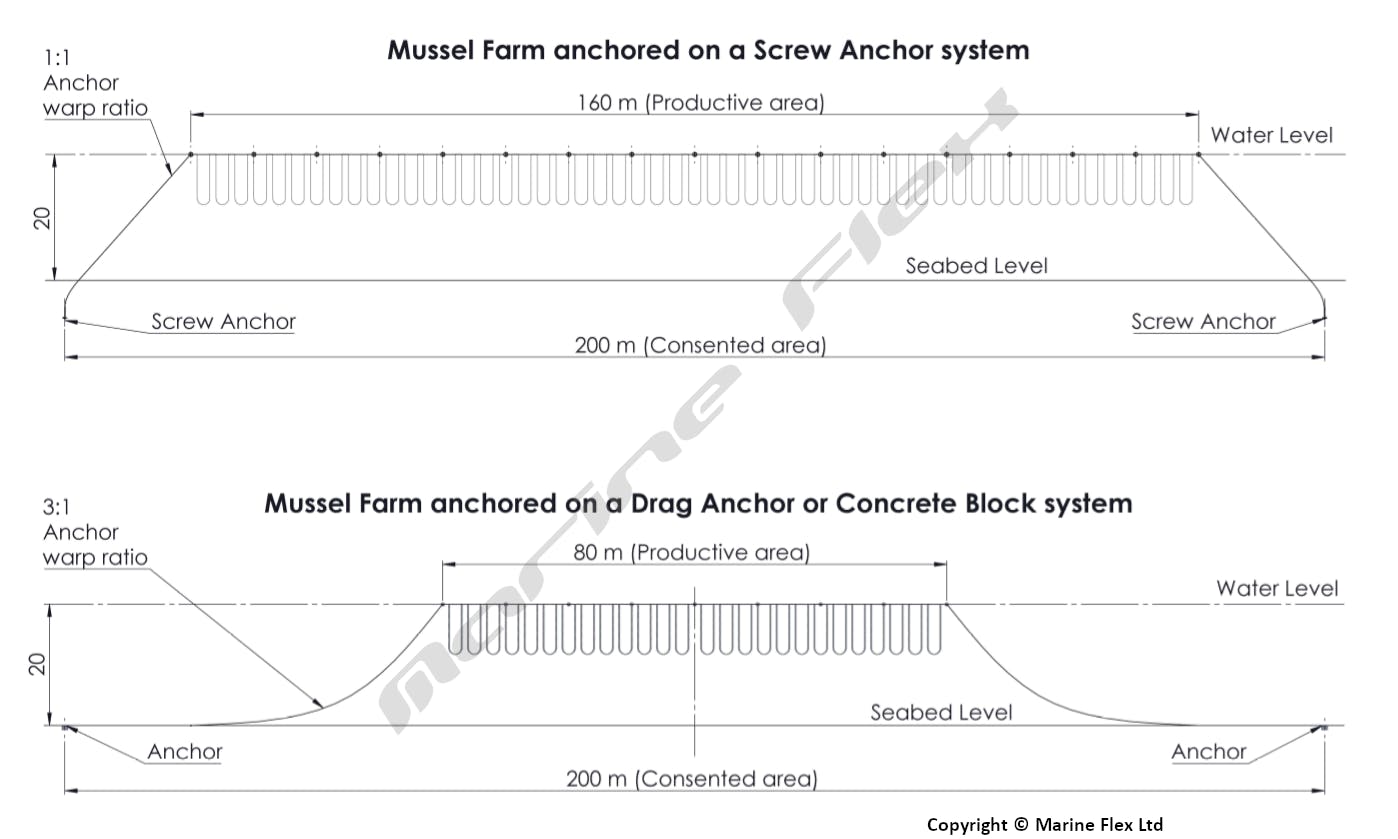

Dive-less system: Allows cost-effective, quick and safe installation in high depth waters, strong current and inclined soil conditions.

Optional Plate Anchor System: Permits installation in very challenging sites where the anchor helix configuration can be quickly adjusted to cope with highly variable substrates.

Helical auger shaft screw anchors: Our Helix Optional Plate Anchor system (HOPAS) built with high-grade tubing anchor shafts permits installation in challenging soil conditions such as penetrating very hard substrates and transitioning from very soft to hard substrates.

True form helix: All our anchors are built using true form helix plates, which ensures weld integrity, permits optimisation of pitch depth per revolution installation (critical for installation performance), anchor holding capacity and sign off.

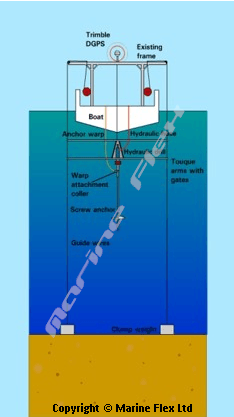

DGPS location system: The installation spot is determined with sub-metre (within 3 in) accuracy even at 100 metres (328 in depth).

Logging software: Records precise installation position, water depth, torque, substrate penetration and anchors attributes.

Static load test method: Safety system to quickly test up to 25T vertical load capacity verifying both anchor and geotechnical capacity before installation of production anchors.

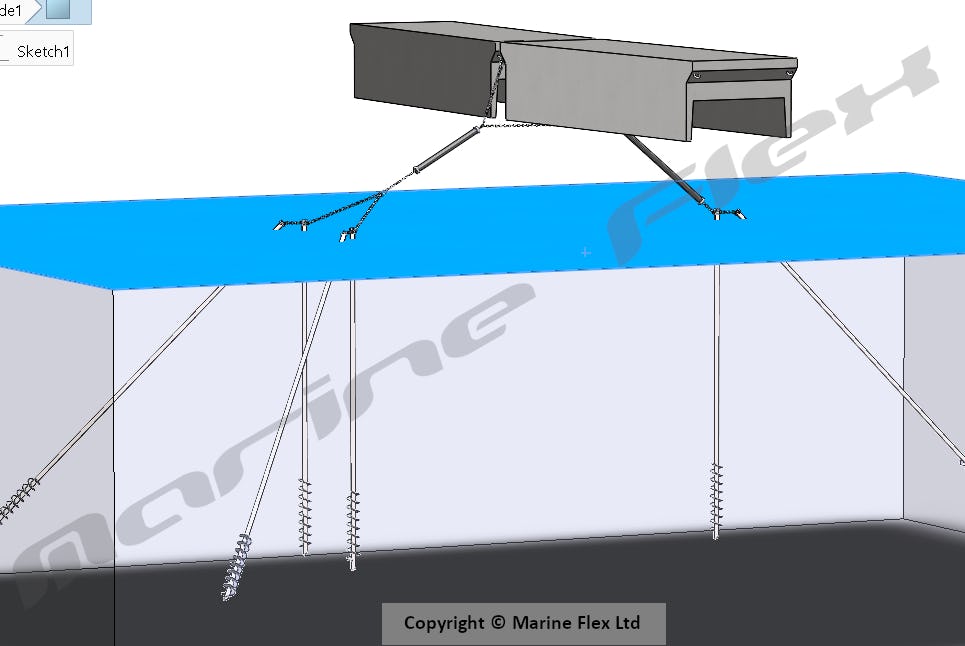

Motion Compensation Gantry system: Higher productivity is achieved as the system allows working in the sea in less clement conditions without which a vessel/work platform would have to cease operation.

Flagging method: Developed to install shaft anchors to “any” depth by adding extensions to the driving shaft.

Geotechnical sampling device: Soil characterisation can be performed either in a preliminary project phase for design and estimation purpose or to refined check on soil homogeneity along the area during installation.